Eastern Overseas Drills Deep with Auger Torque 65000 Max in Oman

Overview

Eastern Overseas, a prominent construction and infrastructure development company based in Muscat, Oman, undertook a critical project involving the installation of foundation piles for high voltage transmission line towers. The project demanded high-performance drilling equipment capable of handling and large-diameter & deep holes in challenging soil conditions.

Challenge

The terrain in the project area consisted of a mix of compacted sand, rock layers, and varying densities of subsoil, requiring a reliable and powerful drilling solution. Eastern Overseas needed an attachment compatible with their Doosan 360 LGA excavator that could provide high torque and efficiency while maintaining precision and stability.

Solution

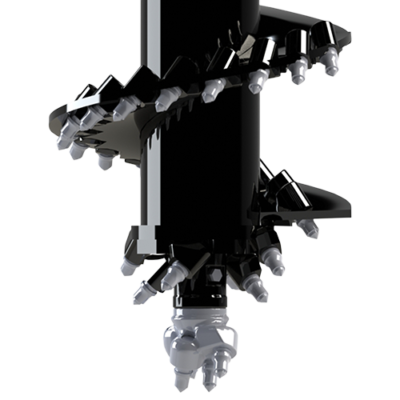

To meet these requirements, Eastern Overseas selected the Auger Torque Earth Drill 65,000 MAX attachment. This high-torque earth drill was paired with:

- A cradle hitch for secure mounting and minimized lateral movement,

- PA Augers specially configured for the job:

- An 800mm diameter / 4000mm CFA auger for deep continuous flight augering,

- An 1000mm diameter / 2500mm auger for shallower foundations and tighter spots.

This combination allowed for rapid and precise drilling with minimal disruption, even in challenging ground conditions.

Results

- Efficiency Gains: Drilling times were significantly reduced compared to previous methods At one third of the operating cost as compared to the use of a dedicated drilling rig.

- Versatility: The setup allowed Eastern Overseas to switch between augers depending on specific pile requirements and terrain. This allows the customer to use the same carrier machine for multiple applications.

- Accuracy: The robust cradle hitch and auger configuration provided excellent control, ensuring correct alignment and depth.

- Reliability: The equipment performed without failure over extended usage periods, demonstrating its durability in harsh Omani weather conditions.

Client Feedback

Eastern Overseas expressed their satisfaction with the performance of the Auger Torque setup, noting the ease of integration with their existing fleet and the equipment’s ability to meet project timelines without compromising on quality or safety.

Earth Drills

Earth Drills  Hitches & Frames

Hitches & Frames  Augers & Extensions

Augers & Extensions  Screw Pile Torque Heads

Screw Pile Torque Heads  Hard Rock Augers

Hard Rock Augers  Sweeper Broom

Sweeper Broom  In-Site Range

In-Site Range  Hammer Range

Hammer Range  Cold Planer

Cold Planer  KDC Drum Cutters

KDC Drum Cutters  Demarec Crusher

Demarec Crusher  Vibro Hammer

Vibro Hammer