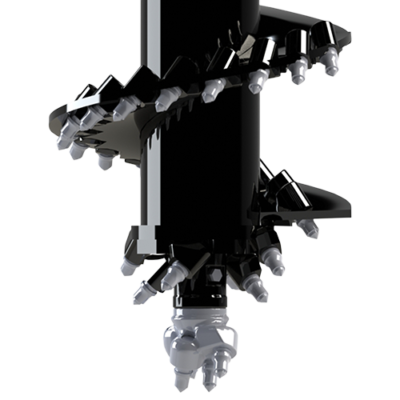

Tata Hitachi acquired the innovative KSR40 Vibro Ripper by Kinshofer

Job in Hand:

As part of a tender for Bharat Coke and Coal Limited (BCCL), Tata Hitachi Construction Machinery India Pvt. Ltd. needed a solution for a coal mining application that ensured optimum productivity and acted inline with Government regulations. Having considered a hydraulic hammer, they introduced the innovative KSR40 Vibro Ripper.

Why KSR40 Vibro Ripper?

The latest regulations introduced by the Government of India, meant that jobsites situated in close proximity to tier 2 and tier 3 cities had to maintain strict noise levels and contractors are required to halt their work activities after 5:00 pm, often resulting in a negative impact on overall productivity. The Vibro ripper has eccentric vibration technology, ensuring that noise levels are kept below 90 dB when measured at a distance of 10 meters from the operational site. This stands in stark contrast to a hydraulic 4T hammer, which registers noise levels of 110 dB when measured at the same distance. This remarkable reduction in noise allows contractors to extend their working hours and, consequently, double their productivity to ensure the completion of the job in the required timeframe

In addition to the noise reduction advantage, most Vibro rippers available in the market tend to cause wear and tear on the excavator’s arm when used continuously. The KSR40, on the other hand, is equipped with dual air springs and four rubber dampeners, significantly mitigating the impact of vibration on the excavator’s arm. This not only enhances operational efficiency but also reduces maintenance costs on the most expensive asset

Furthermore, a key distinguishing feature of the KSR 40 is its modular functionality. It can easily transition between being a ripper, chiseller, and compactor, offering a versatile 3-in-1 functionality that greatly appeals to customers. The ripper function is suitable for use in soft to medium strata, while the chisel option is well-suited for extremely hard strata. Additionally, the compactor function serves the purpose of soil compaction, adding to the product’s versatility and attractiveness to potential buyers.

Impact

Following purchasing the product, Tata Hitachi conducted a live demonstration in the presence of the customer. During this demonstration, the customers observed that the productivity of the Vibro ripper was twice as effective as that of a hydraulic hammer. Furthermore, they noted that the Vibro ripper’s vibrations were notably isolated to the lower half of the machine, thanks to the dampeners. The customer expressed high satisfaction with these findings, leading to the purchase of an additional 5 units up to the present date.

Earth Drills

Earth Drills  Hitches & Frames

Hitches & Frames  Augers & Extensions

Augers & Extensions  Screw Pile Torque Heads

Screw Pile Torque Heads  Hard Rock Augers

Hard Rock Augers  Sweeper Broom

Sweeper Broom  In-Site Range

In-Site Range  Hammer Range

Hammer Range  Cold Planer

Cold Planer  KDC Drum Cutters

KDC Drum Cutters  Demarec Crusher

Demarec Crusher  Vibro Hammer

Vibro Hammer