Major UAE Contractor uses Auger Torque for Micro Piling Project as part of Khalifa Port Expansion

OVERVIEW

2019 Abu Dhabi Ports started their $1bn expansion of its flagship Khalifa Port. This project is expected to increase handling volumes by providing deep-water access and enhanced infrastructure.

Part of the project entailed the drilling of 120 foundation pits, with holes of 1.2m diameter and a depth of 5m. This is often seen as a simple application; however, the drill points were in close proximity to the seashore, resulting in a job site with a very high-water table. Therefore the water ingress during the drilling process coupled with collapsible ground conditions made it difficult to deploy a standard drilling system.

“One of the major benefits for us was the cost efficiencies; mobilization cost was minimal, and the capex investment was a fraction of what we thought we’d have to invest. We can now use the drilling attachments for further projects. We are currently using the equipment for drilling footings for street lighting and potentially some micro piling applications. Auger Torque were able to turn our project from a challenging predicament to a manageable solution”.– Mr Raghunath Bhaskaran – Head of Operations – Saif Bin Darwish.

APPROACH

SAIF BIN DARWISH – Saif Bin Darwish were aware that undertaking the project “in house” would require investment in a dedicated drilling rig which could result in substantial capex expenditure, equipment rental cost and a risk of limited internal know how in executing this application. They therefore approached Auger Torque, who recommended a modular solution, where a hydraulic drill could be fitted onto the excavator to drill the holes, mounted, or dismounted with minimal time loss.

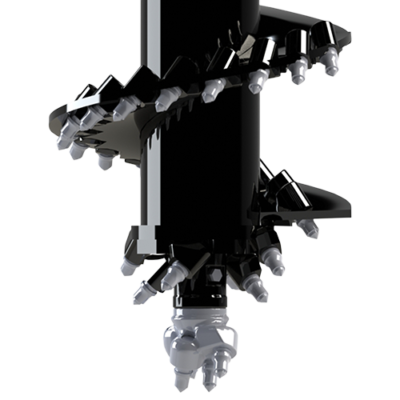

Auger Torque proposed 50000 max Earth drill be fitted on the Sany 335excavator, where in the torque generated by the drive would enable drilling the 1.2 m Ø to the depth of 5 m. It was critical that not only the system work but the drive unit should be able to drive the casing in, drill the holes and should be robust enough to carry the weight of the auger and the spoil – debris.

Auger Torque’s engineering department conducted Finite Element Analysis to ensure the shaft of the drive unit would be able to take the tensile load of the casing and Auger with the spoil at 5m depth. To overcome any issues of the hole collapsing during the drilling process, a 1200mm diameter casing was supplied with a 1190 mm special Auger. Test information was submitted and a JSA (Job safety advise) and method statement was completed and submitted resulting in the system being approved to meet all criteria.

The 1200mm casing with auger was positioned at the drill point and was driven into the ground. Once set in the ground, the casing top adaptor plate was unlocked, and the auger was inserted in and the isolated soil inside the hole was drilled out. The casing prevented the walls of the hole collapsing and ensured the bottom of the drilled hole was clean and flat, a SANY225 excavator was fitted with a 25,000 NM drive unit with an extension tube and a cleaning bucket to remove the residual from the hole.

Earth Drills

Earth Drills  Hitches & Frames

Hitches & Frames  Augers & Extensions

Augers & Extensions  Screw Pile Torque Heads

Screw Pile Torque Heads  Hard Rock Augers

Hard Rock Augers  Sweeper Broom

Sweeper Broom  In-Site Range

In-Site Range  Hammer Range

Hammer Range  Cold Planer

Cold Planer  KDC Drum Cutters

KDC Drum Cutters  Demarec Crusher

Demarec Crusher  Vibro Hammer

Vibro Hammer